|

Product Details:

|

| Place Of Origin: | Shandong, China | Condition: | New |

|---|---|---|---|

| Video Outgoing-ins: | Provided | Warranty: | 3 Years |

| Core Components: | PLC, Engine, Gearbox, Motor, Gear, Pump | Dimension(L*W*H): | 3500*3200*2800mm |

| Certification: | ISO9001:2008/CE | Weight (KG):: | 8000 Kg |

| Applicable Industries: | Rubber Machine | Roll Material: | Chilled Cast Iron |

| High Light: | 4 Roll Rubber Calender Machine 15KW,450x1400 Rubber Calender Machine |

||

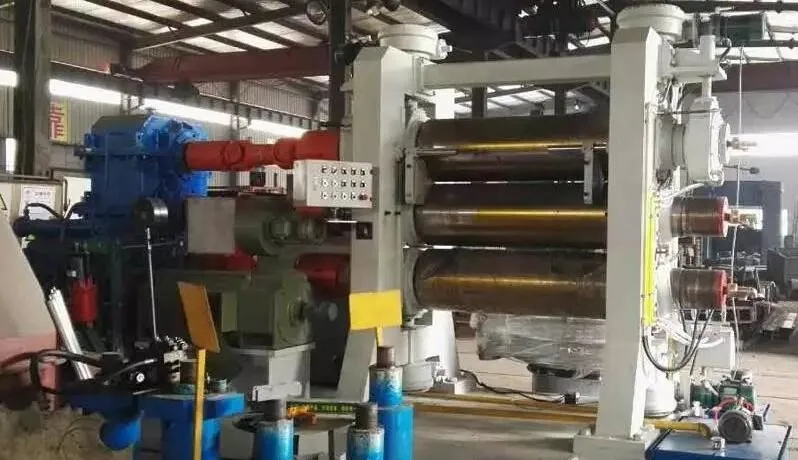

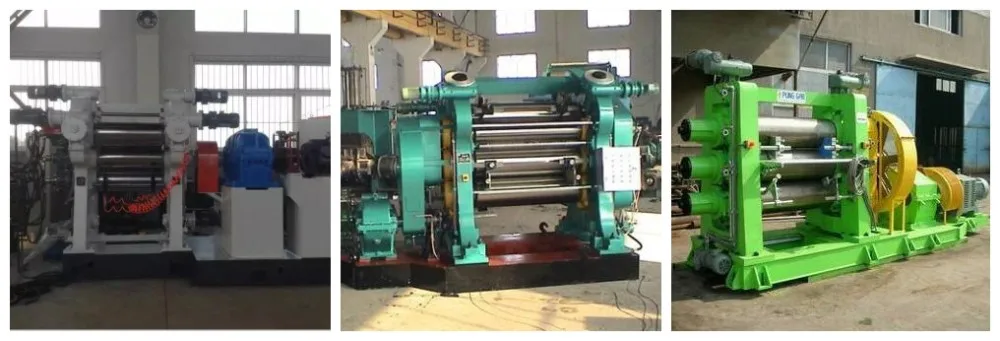

Four roller rubber calender machine is mainly using for fabric, canvas and others fabric continuation rubberizing single or double sides, and also production rubber sheet.

1) Calender line for coating textile tire cord fabric (tire industry).

2) Calender line for inner liner, rim cushion and rubber sheet laminating (tire industry).

3) Calender line for coating textile conveyor cord fabric.

4) Calender line for industrial rubber film and sheet.

Four roller rubber calender is consisted of bedplate, frame, rollers, motor, coupling, gearbox, adjusting spacing device, the adjusting temperature device of roller, etc .

Features:

1) The bedplate is whole model, installation convenience.

2) Rollers are made of chilled cast alloy iron, the working surface of roller is hardness and smoothly. steam and cooling water can pass through inner of the rollers so that surface temperature can be adjustable.

3) Adopt roll bearing, high precision, long service life, axes pathway is no abrasion.

4) Full range of bending deflections is optional including middle height, inflection and axis crossing.

5) Adjusting spacing device is consisted of one left and one right hand wheel. The bearing bases need is moved and reached nip by worm and worm wheel. Roller space can be adjusted manually or by electric motor.

6) Roller arrangement can be “I” type, “F” type, “Z” type, “L” type and “invert L” type.

7) The speed reducer is the hard-tooth surface gear reducer of Class 6 precision, which has long service life and low noise.

8) Perfect emergency stop device can ensure the safety of person and equipment.

We may design and produce it as per customers’ requirements, equip various accessories, composing combined product line. Below is the main parameters:

| Model | XY-230X630 | XY-360X1120 | XY-400X1400 | XY-450X1500 | XY-610X1730 | XY-710X2130 | XY-810X2430 |

| Roller Diameter | 230mm | 360mm | 400mm | 450mm | 610mm | 710mm | 810mm |

| Roller Working Length | 630mm | 1120mm | 1400mm | 1500mm | 1730mm | 2130mm | 2430mm |

|

Middle Roller Linear Speed (m/min) |

2.1~21 | 2~20.1 | 3~26.39 | 2.5~25 | 8~50 | 3~30 | 2~20 |

| Nip Adjust Scope(mm) | 0.1~10 | 0.1~10 | 0.1~10 | 0.1~10 | 0.1~15 | 0.1~15 | 0.1~15 |

| Max Calendering Product Width | 500mm | 920mm | 1200mm | 1300mm | 1500mm | 1900mm | 2150mm |

| Power | 15KW | 55KW | 75KW | 110KW | 160KW | 185KW | 280KW |

| Weight (kgs) | 4800 | 11000 | 22000 | 26000 | 52000 | 67000 | 94000 |

Step 1: Machine main body and accessories rust preventing oil treatment.

Step 2: Wooden Carton or stretch film packing.

pvc film 4 - roll calendaring machine

Our Advantage is?

|

1. The rolls Made of chilled cast iron of vanadium and titanium alloy. Roll face is hard and anti-wear. For heating up or cool down, the rolls are either circumferentially drilled or centrally bored so as to make temperature well proportioned on the roll surface. |

2. Transmission System Hardened tooth-surface reducer, Compact structure Higher transmission efficiency Lower noise Longer Service Life. |

|

|

|

3.Electric-Control System Imported PLC Device Full-Automatic Control Easy to exchange the modes and reliable to operate the controller. |

4. Bearing&Sealing Bearing:Provide15years Service! Sealing:Provide10years Service! High-intensity Seal Ring Promise the oil will not leak Provide 10 years Service! |

|

|

5.The machine is driven by DC motor with a wide range of speed adjustment. Working linear speeds can be steplessly regulated within the fixed range for different applications.

6.The rolls are equipped with lubrication failure alarm device, as well as nip display and speed display.

7.The rolls can be arranged in L, Γand I forms. The top roll has a camber that can eliminate bending impact on the roll in working process. Thus, it is possible to make products with same thickness along axial direction.

8.The machine is equipped with emergency device. When an emergent accident occurs, the calendar will be immediately stopped to open the roll space so as to protect the operator and equipment.

![]()

![]()

![]()

![]()

Contact Person: Miss. Sophie

Tel: +8613573826806